product details / scope of delivery

Description of the MBT 6200 LON:

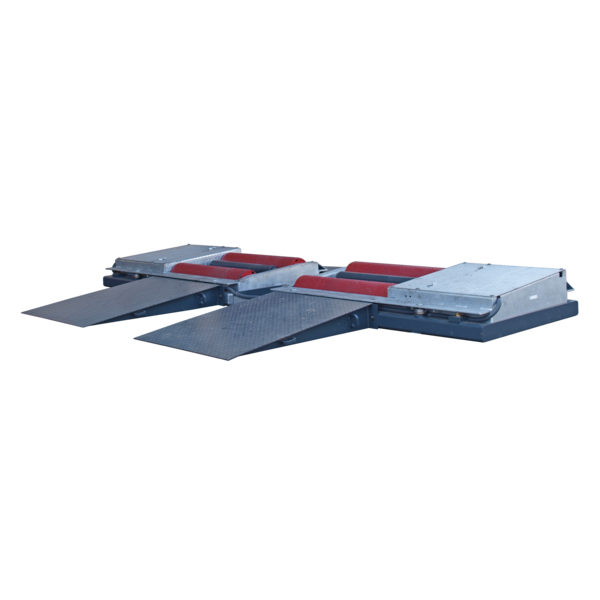

Roller brake tester, particularly for agricultural vehicles

and special vehicles with an axle load of up to 18 t

- The large roller axle distance means it is designed particularly for agricultural vehicles or special vehicles with large wheel dimensions.

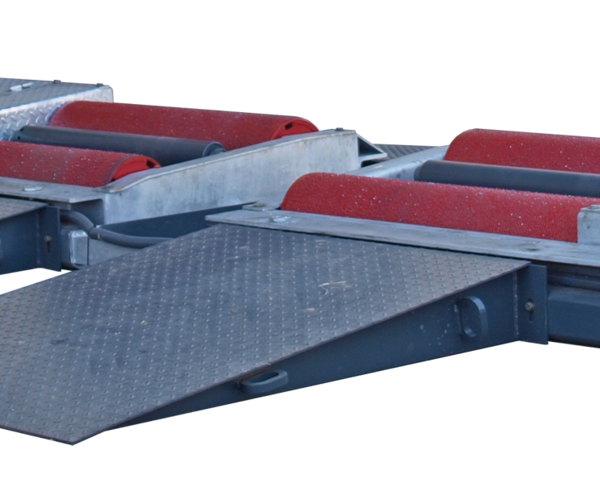

- The considerably elevated test rollers prevent the wheel from jamming on the frame, even when testing vehicles with low-pressure tyres

- DC brake supplied as standard makes it easier to drive on and off with the axle driven by the vehicle.

- Multi-analogue display with two pointer indicators

| (Diameter: 2 x 350 mm) | |

| - Measured value display | 0 - 4 kN / 0 - 40 kN |

- Display option for:

- Braketester

- Wheel arch tester

- Shock absorption tester

- Difference display (three-digit + LED bar) for displaying:

- Difference in braking force in %

- Difference in shock absorption in %

- Deviation in wheel arch in m/km

- Results evaluation using additional coloured LED bars

- User guidance using alphanumerical display

- Program control using 32-bit microprocessor electronics

| enables the finest resolution for the measurement results | |

| * Dimensions of display(H x W x D) | 910 x 870 x 300 mm |

- Comprehensive package of functions for professional testing, such as:

- Delayed automatic switch-on after entering the tester

- Automatic start-up monitoring supplied as standard to avoidtyre damage

- Automatic slip cut-off with pointer stop and automatic restart already included as standard

- Automatic exiting aid supplied as standard to enable the driven axles to conveniently exit the tester

- Automatic cut-off after exiting the tester

- Single-wheel switching for differentiated consideration of each wheel

- Robust and long-lasting design due to:

- Electronic, temperature-compensated strain gauge system for highly precise measurement results under all environmental conditions

- Roller surface welded

- Optional, free plastic coating on the test rollers

- 32-bit microprocessor electronics for process control and monitoring of all the safety functions

- Lockable main switch

- RS 232 interface connection

- Splash-proof motors work reliably, even under high-stress environmental influences

- Weighted test rollers with groove ball bearings ensure maximum precision and complete driving comfort and guarantee a long service life for the entire tester

- Internationally recognised TÜV certificate as per issue 149/2021 of the Verkehrsblatt [German Transport Gazette]

- Star-delta circuit to avoid high inrush currents

- Centre cover between the roller sets

- RS 1 roller set design with motors on the side

- Rear roller elevated by 50 mm - guarantees highly precise measurement results, particularly for trailer axles.

- Self-supporting divided roller set

- Varnished with high-quality powder coating: Anthracite Grey, RAL 7016

Scope of delivery:

- Analogue display with two pointer indicators and an integrated switch cabinet

- MBT 6000 RS 1 roller set with preparation for weighing equipment

Downloads

Sales documents

| Brochures | ||

|---|---|---|

|

Brochure MBT-SERIES for all vehicle classes

|

||

|

Brochure (Printable version) MBT-SERIES for all vehicle classes

|

||

| Technical Datasheet | ||

|---|---|---|

|

Technical Datasheet MBT 6200 LON W CLASSIC

|

||

|

Technical Datasheet (Printable version) MBT 6200 LON W CLASSIC

|

||

Technical documentation

| Operating Instructions | ||

|---|---|---|

|

Operating Instructions MBT LON

|

||

Technical Data

Technical data:

| Axle load (can be driven over) | 18000 kg |

| Min. track | 400 mm |

| Max. track | 3600 mm |

| Drive power | 2 x 11 kW |

| Test speed | 3 km/h |

| Roller length | 1600 mm |

| Roller diameter | 265 mm |

| Roller axle distance | 685 mm |

| gG fuse | 63 A |

| Power supply | 3/N/PE 400 V 50 Hz |

| Dimensions of roller set (L x W x H) | 5580 x 1340 x 370 mm |