13.01.2020 / Press Release

With the “Directive 2014/45/EU of the European Parliament (...) of 3 April 2014 (...)”, standardised minimum requirements were defined throughout Europe for regular technical vehicle inspections. This Directive enters into force on 20 May 2018, but gives the individual member states the opportunity to accredit non-compliant testers over an additional period of five years. The potential and recommended use of a axle play detector during the testing process, which must however meet certain requirements, is a new addition to this Directive. MAHA, the Allgäu-based workshop supplier, is already offering appropriate solutions today so that vehicle inspections can be carried out in compliance with this Directive in future.

Haldenwang, 23 February 2018. Some changes which should be taken into account in good time so that the requirements made can be met once the transition period has elapsed at the latest will come into force with effect from 20 May 2018 as a result of Directive 2014/45/EC of the European Parliament.Workshops and test organisations would do better not to delay and purchase appropriate equipment in good time.

Playing it safe with MAHA

In future, there will be a few extra aspects to take into account during the inspection process compared to the existing specifications: If, during the regular vehicle inspection, defects and wear of safety-related components such as the steering, axles, suspension, etc., have to be checked using a axle play detector, it must comply with the minimum requirements set down in Annex III of Directive 2014/45/EU once the transition period elapses at the latest.

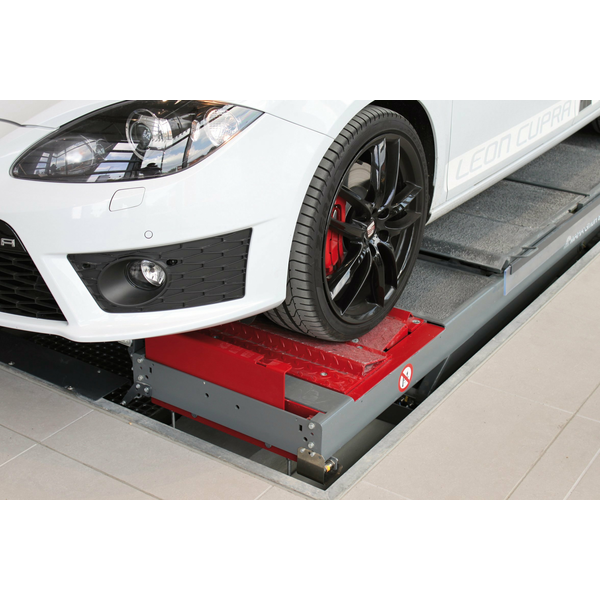

The axle play detector used must be equipped with two power-driven test plates which can be moved away from one another in opposite directions, both lengthwise and crosswise. Units with only one test plate will no longer be permissible according to the Directive from May 2023 onwards at the latest. MAHA axle play testers have two test plates and thus guarantee a high level of testing efficiency. Even if vehicles have a modern single-wheel suspension where the suspension arms of the axle structure are often installed clamped together, the axle play testers from Haldenwang offer testers the flexibility they need to be able to reliably check even these bearing positions in a loaded state.

A total travelling distance for each test plate of at least 95 mm and a travelling speed of between 5 cm/s and 15 cm/s are also stipulated for testing vehicles with a permissible total vehicle weight of more than 3.5 t. The MAHA axle play detectors with appropriate configuration even meet these specifications without any problem.

High-quality, durable and convenient

Due to their hydraulic drives, the axle play detectors from MAHA also offer high test forces – which is a huge benefit, particularly when it comes to heavy vehicles and if the complete vehicle is to be made to vibrate. Thanks to slide bearings with round guides made of hard chrome-plated steel and robust and generously sized hydraulic cylinders, the MAHA axle play detectors promise a very long service life in everyday testing applications with a throughput of several vehicles per day. The low-noise low oil-immersed unit and operation using a cable-free and ergonomic hand lamp with an extremely bright LED light also offer convenient working conditions. All of the above are arguments which not only illustrate compliance with the Directive, but also show that the MAHA product is of a high quality!