13.01.2020 / Press Release

This topic also under

MAHA UK understands quality and reliability are two crucial demands of customers when approached about MOT equipment, so when South Street Motors approached the workshop equipment manufacturer about a potential installation following a recommendation, it was keen to emphasise those points from the start.

Cambridgeshire, 21st February 2022. MAHA UK Regional Sales Executive, Luke Fuller, knew the customer, South Street Motors Group Managing Director, Jonathan a’Court-Wills, had done his research and been impressed by what he had found in terms of quality of equipment, company history and reputation. As a result, Luke was keen to continue that impressive start!

He said: “Jon and I discussed South Street Motors’ needs and what the company was looking to achieve from the installation, at which point we provided Jon with a bespoke quotation for what we felt met the business’s needs, after which I offered to travel down to complete a site survey and initial sketch of the site.

“Once the survey was completed, Jon proceeded with the order of the equipment.”

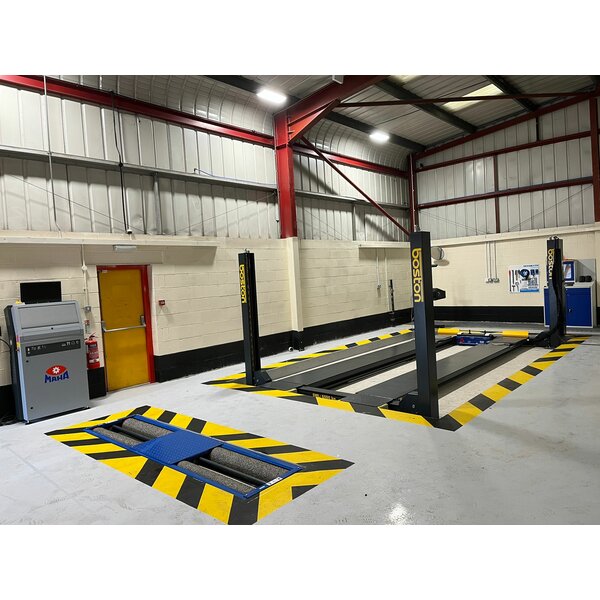

· Boston Class 7 – 6.1m, 6T four-post lift, with LED under vehicle lighting and Majorlift 2.8T jacking beam

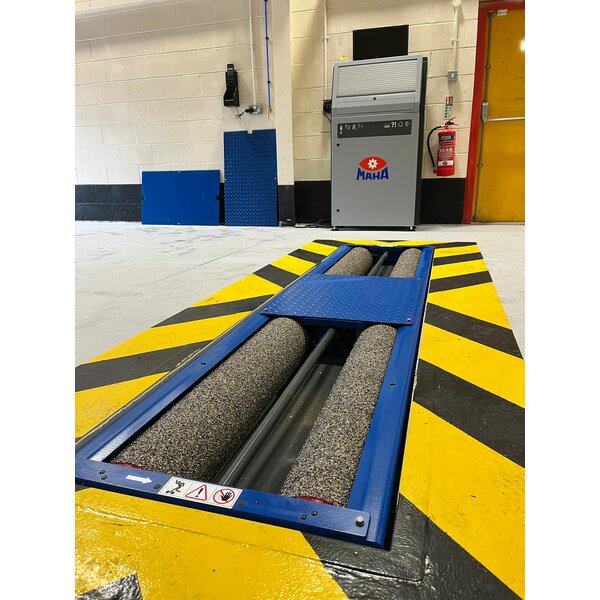

· MAHA MBT 2250 Class 7 connected brake tester with dynamic weighing

· MAHA MLT 1000 headlight beam tester with stainless steel rails

· MAHA full MOT pack, including boards, tools and convex mirrors for ATL testing

Luke continued: “I then produced a full CAD drawing of the building and positioned the quoted equipment discussed to meet the DVSA Class 7 regulations. At that point, Jon could make his VT01 application with the DVSA, where some alterations were made, such as extra dimensions and customer viewing areas.”

To ensure a smooth process from start to finish, emphasising MAHA UK’s dedication to the customer and desire to see the job through to the end, Luke was always on-hand, whether it be on the phone, e-mail or, indeed, travelling down to the site in Somerset.

Luke had regular discussions with the groundwork team, for instance, to ensure the plan was carried out to specification, which was aided by the original CAD drawing to help with positioning. That accuracy allowed the installation to be carried out over a couple of days.

Jon echoed that point: “Simply, the service and support were first class. Nothing was too much trouble; Luke guided us through the process with detailed drawings and site visits and the installation team were very professional and helpful – at no point was I required to have an input regarding the installation!

“Communication was excellent; Luke was always available on the phone. I would most certainly recommend MAHA to anybody thinking of installing this type of equipment.”

As South Street Motors adapts to the newly-installed equipment, MAHA UK’s work doesn’t end there, with training set to take place in the spring.